Automation Synergy is a leading process automation company offering perfectly customized industrial automation and engineering solutions. With a penchant for effective problem-solving, consistent delivery, and maintaining quality client relationships, we have excelled and stood the test of time.

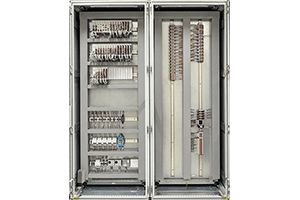

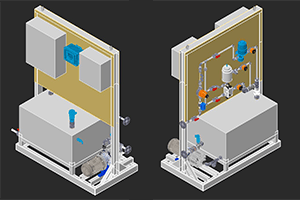

We offer a complete package, from initial development to on-site installation. A dedicated team takes care of Engineering, Supply, integration, assembly, testing, and site services for industrial process instrumentation and control projects, covering all stages of a project’s life cycle.

Our workforce has experience and knowledge in integrated project management and design processes. Years of experience and expertise make us capable of providing cost-effective solutions for the smallest operations to the largest control systems.

We are synonymous with excellence and have earned a reputation as a solution provider for the most challenging projects in our industry.

We Deliver

Record Breakers

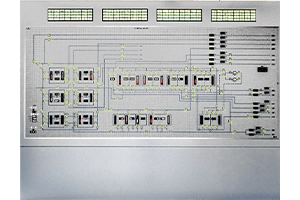

In order to minimize the threat to the safety of the workforce caused by the system outage, an emergency shut-down task was successfully accomplished in the record time of 4.5 hours, where 11 cabinets having Fire and Gas signals with more than 4000 terminations were replaced completely.

We have set the record for planning and supervising the replacement of over 70 cabinets with more than 14,000 terminations, and loop checking from the field, by accomplishing all of this within seven days.

We designed and manufactured swing frames for EMERSON MARATHON OIL to mount a new system and marshalling components. These were installed in existing cabinets on-site during a hot cutover job. A hot cutover job is the process of migrating from an old to a new system without disrupting plant operations.

For SABIC’s MCC (Motor Control Centers) Replacement System, Main Automation Contractor (MAC) interfaces with significant automation systems like Honeywell, Invensys, and Yokogawa.